About 9% of funded Kickstarter campaigns fail to deliver on their promises, and hardware projects have a special set of challenges that project creators have difficulty overcoming. While software teams can release a minimum viable product, then iterate and improve upon it, hardware teams have less room for iteration once they ship their device.

We traced the downfalls of 25 funded-but-failed hardware projects to better understand where they went wrong, and how you can avoid making the same mistakes. These campaigns were selected based on information availability – projects whose updates were entirely restricted to “backers-only” were not included, for instance. We then collected data on the difficulties these campaigns faced by reading and topic coding a few hundred project updates, interviews, articles, and postmortems from the failed hardware projects.

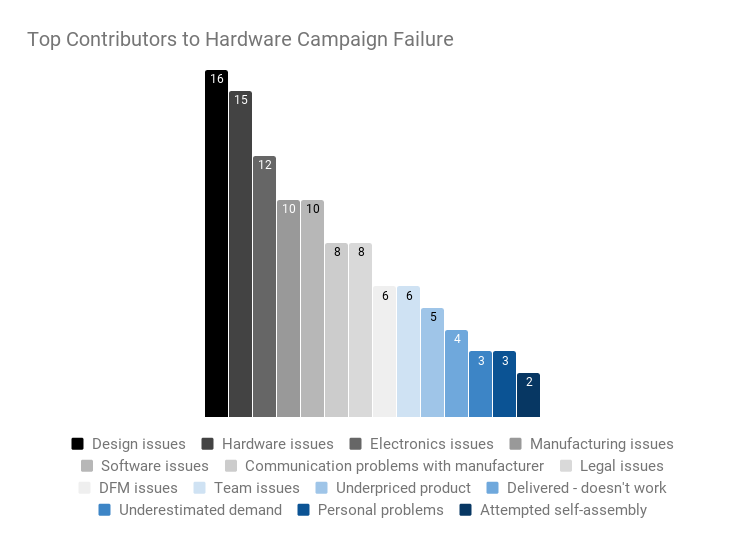

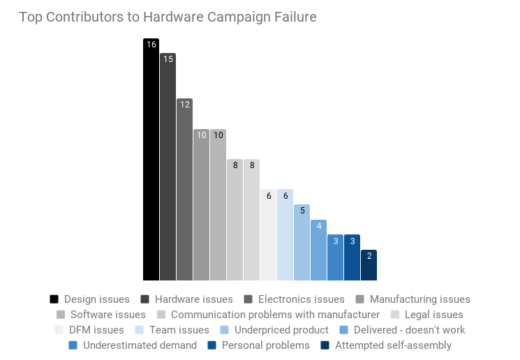

Contributors to hardware campaign failure

#1: Design issues

Design and hardware issues were the two most common contributors to project failure – both affected more than 50% of campaigns. Design problems that were not caught early on resulted in difficult (or impossible) to-use products, like game controllers with edges sharp enough to break the skin, or drones that were too fragile to land.

Even design problems caught immediately caused major problems for some projects. For instance, the team behind the iControlPad 2, a mobile keyboard / game controller, realized they had forgotten to include backlighting for their keyboard the day after they raised $209,000 on Kickstarter. They immediately tried to fix their mistake, but doing so required modifying the keymat design and coating, adding an extra layer of PCB, and redesigning the controller’s case. Two years later, the added costs of the redesign proved to be too much for the team, among other problems.

The building blocks designers chose for their projects mattered, too. Failed project creators lamented trying to build products from the ground up instead of using off-the-shelf components, which are cheaper and easier to source than custom ones.

What can I do to avoid this?

Hire a designer. If you can, have a hardware product designer work with you to create your product from the get-go. Someone with experience in your industry is a particularly valuable asset. Alternatively, if you choose to enlist the help of an original design manufacturer (ODM), the manufacturer will work with you to design and make your project based on your high-level specifications (though this approach entails certain risks for IP, contractual restrictions, design flexibility, and pricing).

Prototype early and often. Major design issues are often easiest to find by testing prototypes. Make prototypes of your earliest designs and expose them to as much feedback as you can – this will be much less costly than sinking your time and money into manufacturing a product with fundamental design flaws.

Tear down similar products to understand how they work, especially if this is your first time building this type of hardware.

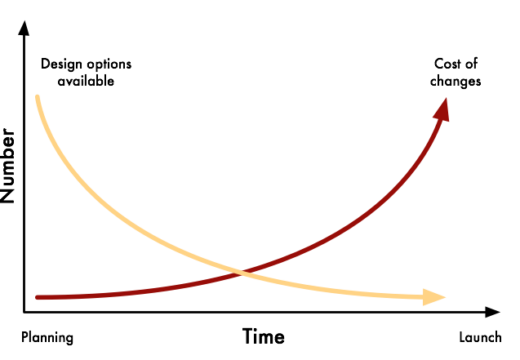

Find and fix design issues as soon as you can. Vera Novak made this graphic for a post on the construction industry, but it rings true for hardware development, too:

Design planning and cost of changes

The design and planning phase is the cheapest, most flexible point in time you have to fix your product. Take advantage of that.

Your early prototyping phase is the next best time to catch these flaws. Be sure to develop looks-like and works-like prototypes to test the aesthetic and function of your product, and get as much feedback on these prototypes as you can. Run them by your team members, friends, friends-of-friends, neighbors, parents, children, pets – really, everyone you can find. The earlier in this process you start getting feedback, the better.

Test your product. You’re sending your invention into a world full of dynamic environments and clumsy humans. Your product may have to deal with extreme temperature changes, water, dust, dirt, and sudden impacts, not to mention the regular wear and tear of everyday use. NTS has an extensive list of environmental tests you should consider for your product, as well as hardware/software tests, materials tests, mechanical tests and more. Some design flaws can be difficult to recognize until the product is in everyday use – these tests help catch those problems earlier.

#2: Hardware issues

Hardware components proved challenging for project creators to design, especially when weight, temperature, or pressure factored into product performance. The Techject Dragonfly and ZPM Espresso Machine were two such products.

When coffee lovers and then-recent graduates Gleb Polyakov and Igor Zamlinsky set out to build a new espresso machine, they had a jury-rigged prototype and a goal of bringing commercial-grade espresso to the masses. However, working with pressurized, boiling water can be a dangerous game for even the most experienced engineers, and Polyakov and Zamlinsky were just beginning their careers. Early prototypes of the machine had water “spurt[ing] halfway across the room”, and later ones sported deflecting panels under high pressure. After addressing design and quality issues with the espresso machine’s shell, the team managed to get 50 units off the line for a beta test – these units suffered from disconnected displays, sticking buttons, misassembled steam wands, leaking discharge tubes, and rupturing drain tubes.

In the end, the project’s death blow was a combination of team problems and a lack of manufacturing finances, but its hardware shortcomings might have been avoided had the team learned about tolerancing before they were 2 years into the project.

Igor Zamlinsky went on to work on the TechJect Dragonfly, a winged, modular camera drone that was based on robotics research from Georgia Tech. The necessarily light weight of the drone combined with the mechanical intensity of beating “wings” made for some difficult hardware challenges. The team had significant problems with the drone’s wings, transmission gears, servo system, and overheating chips, among other components. Ultimately, TechJect was unable to bring a robust product to market. All that remains of the Robot Dragonfly is a $384 wooden model kit from the Philippines, priced at nearly 4 times the cost of the functional drone the TechJect team dreamed of.

What can I do to avoid this?

Hire a mechanical engineer if your product includes many mechanical parts. Even if it doesn’t, it may be a good idea to consult with one for your product’s enclosure design, for instance.

Choose a reputable manufacturer. Getting a product manufactured at scale can be a difficult thing to do without past manufacturing experience. Luckily, crowdfunding websites are now building infrastructure for project creators to use. Kickstarter is working to develop a Hardware Studio to more easily move projects from design to manufacturing, and Indiegogo offers partnerships with Arrow to help bring your ideas into production.

Understand hardware design basics or hire someone who does. Take this lesson from the ZPM espresso machine team: if you don’t know how to tolerance your parts, those parts have no business being in a finished product.

#3: Electronics issues

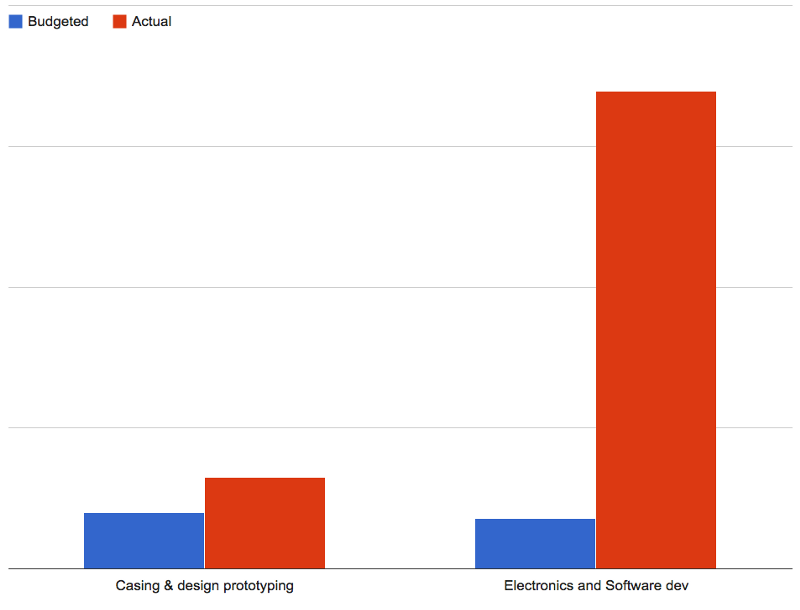

Custom electronics can be costly and difficult to build. All but one of the failed hardware projects we reviewed contained electronics of some sort, and half of those projects had electronics-based difficulties during the development process. From lamination processes short-circuiting batteries to finicky thermal elements acting up, electronics failures spanned a broad range of components and applications. Project creators who ordered custom PCBs opened shipments to find faulty units – an especially costly mistake when ordering in bulk. Fixing these problems really adds up: for the Triggertrap Ada, a modular camera trigger, bundled electronics and software development costs wound up being 9.4x more expensive than what they had budgeted for.

Development costs

The Triggertrap cost breakdown, titled “We completely blew our development budget”

What can I do to avoid this?

Hire an electronics engineer. Your product’s electronics design is critical to both the functionality of your product and the safety of your customers. Don’t screw it up.

Order test batches before mass production. While it may be tempting to order in bulk up-front to save money and prove to your backers that you’re making progress, large orders of flawed components are a costly mistake.

Test and certify your electronics. If you’re making a phone case, for example, you need to make sure it doesn’t interfere with the phone’s ability to send and receive RF transmissions. That’s the FCC certification, but your device may need CE, RoHS, WEE, and UL certifications as well. The Consumer Product Safety Commission has a handy chart where you can see what requirements your product has to meet. Budget your time and money to include product testing and compliance certifications.

#4: Manufacturing issues

Manufacturing issues ranged from general quality control problems to manufacturers using the incorrect materialsor processes to save time and money. The Geode iCache and ZPM espresso machine had difficulties with functional adhesives and assembly. In one particularly unfortunate case, the team behind the Kreyos smartwatch alleged that their manufacturer used Kreyos’ resources to make a turnkey smartwatch solution for other companies.

What can I do to avoid this?

Again, choose a reputable manufacturer and build a strong relationship with them. Shopify outlines a couple of useful first steps to take. Kickstarter also has an extensive resource directory that includes recommended manufacturers. Indiegogo provides similar resources in their experts directory.

Do not try to manufacture over the Chinese New Year (if your manufacturer is in China). Many of the project creators who ran into manufacturing delays were unaware of the holiday’s impact on plant operations. The first day of the New Year falls on the new moon between January 21st and February 20th, and celebrations run until the 15th day of the new calendar month. Basically, by the time the holiday season is winding down in the US, it’s just getting started in China. If you’re still aiming to manufacture over the Chinese New Year, this useful guide should help you navigate the schedule changes.

Use different manufacturers for different components if you don’t trust them with your intellectual property. This will almost certainly make your manufacturing process more expensive and time-consuming, but your design will be harder to copy if each manufacturer only has a small part of it.

#5: Software issues

Many projects had problems with their product’s native software or the mobile applications they developed to go with their hardware. Drones and 3D printers lacked functional calibration software, and Bluetooth-dependentwearables had rampant connectivity and app design problems. Location and object tracking for drones was also a common difficulty. It’s easier to iterate on software than hardware after the product goes to market, but terrible software renders even the best hardware unusable. Your earliest backers might be okay with underdeveloped software, but it should still be functional.

What can I do to avoid this?

Hire a software engineer and/or mobile developer – you’ll wind up with a better product in the end – and consult with a UI/UX designer. Unintuitive interfaces can be a huge turn-off for even the most powerful devices.

Test your software. By the time your product is in your customer’s hands, the features you’ve decided to include in your software should work more often than not. Have a quality assurance (QA) process in place for testing your device’s software.

Make update infrastructure. If every other step you’ve taken hasn’t resulted in flawless, timeless software (it won’t), make sure you’ve developed software that can be easily updated. Even if you’re happy with the way your software turned out, people will find security exploits for your devices once they’ve been around for a while, so make sure you can update your product’s software.

#6: Communication problems with manufacturer

While choosing an overseas partner can help cut manufacturing costs, some project creators had difficulty overcoming the resulting time and language barriers. The time difference between the US and Vietnam made it difficult for James Stumpf, the creator of the Levitatr keyboard, to send or receive more than one email a day. Andrew Muldowney, who was trying to make a portable thermal printer, had trouble communicating the difference between a “day” and a “business day” to his manufacturer and wound up with delayed part deliveries. Building a strong relationship with your manufacturer is key, so you should build systems to circumvent communication problems like these.

What can I do to avoid this?

Have someone who can translate. If you’re worried about the language barrier between you and your manufacturer, either hire a translator or make sure that someone on your team is fluent in your manufacturer’s language.

Schedule regular updates. If you’re not able to talk with your manufacturer during normal business hours, build a communication schedule for both of you to commit to at the start of your relationship.

Consider living overseas at the start of manufacturing. Several project creators opted to visit their manufacturers for the first several weeks (or sometimes months) of the manufacturing process to make sure things were going smoothly. You can also hire a China-side project manager to help oversee production.

#7: Legal issues

The legal issues these crowdfunding campaigns faced spanned a wide range of issues: from naming lawsuits to intellectual property disputes, from component shipping problems to compensation problems.

What can I do to avoid this?

Have a legal budget. Hopefully you won’t get sued, but you’ll probably need some cash set aside for navigating intellectual property rights, at least.

Just be careful, please. The legal problems faced by these projects were too varied to provide much specific feedback. Based solely on these campaigns, though: make sure your product name and specs don’t infringe on any copyrights, compensate (and treat) your team fairly, and don’t try to ship lithium ion batteries through USPS.

#8: Designing for manufacturability (DFM) issues

Project creators had difficulty moving from prototypes to production-ready designs, most because 3D printed prototypes have much more flexible design parameters than injection molded final parts. Others had trouble making their designs easy to assemble. Basically, the shape of your parts is limited by the manufacturing process you choose. If you choose to CNC machine some mechanical components, your parts can’t have internal corners. If you’re injection molding parts for a plastic case, it may be difficult to include undercuts or variable wall thickness. Try to keep these manufacturability limitations in mind throughout the design process.

What can I do to avoid this?

Hire an industrial designer. If you design your part for manufacturability from the beginning, you can avoid major sunk costs at the start of manufacturing, like injection mold redesigns.

Choose your manufacturing processes carefully. Make sure the process you choose is the right one for your design and your order size. Take the time to calculate both the setup and unit costs of the processes you’re considering for your parts. It’s okay to spend $50,000+ on tooling if you’re making 50,000 units, but for a run of 2,000, the per-unit costs are a little high. Work with your manufacturer to determine setup costs and unit costs before going into production, and make sure these are in line with the amount of funding you have.

#9: Team issues

These campaigns’ team issues were as varied as their legal issues, and the positions teams didn’t hire for were sometimes as problematic as as ones they filled. For instance, building a hardware product from scratch can be extremely difficult if you’re just “a small marketing team”. Team members may leave for personal problems, or walk out at inopportune times. You need to make sure you build a good team and treat them fairly.

What can I do to avoid this?

Hire for the right positions. If you don’t have substantial experience in every aspect of the design, prototyping, and production phases of getting a product to market, find other people who do. Even if you think you have enough experience, you probably don’t have enough hours in the day to effectively fill every role. Check out Indeed, Monster, and LinkedIn to find people with the skillsets you need.

Hire the right people for those positions. Getting a crowdfunded project off the ground can be an intense process. While it’s important to find experienced people to for your team, make sure they can handle the pressure (and make sure you can, too).

Treat your team well. When you set your crowdfunding goal, factor in wages for the team you plan to build. Check out the Bureau of Labor Statistics, pick the professions you need, and calculate expenses based on your projected timeline. Build a culture that supports the wellbeing of your team – keep healthy working hours and conditions, communicate clearly and effectively with your teammates, and make sure to balance the demands of your project with the risk of your team burning out.

#10: Underpriced product

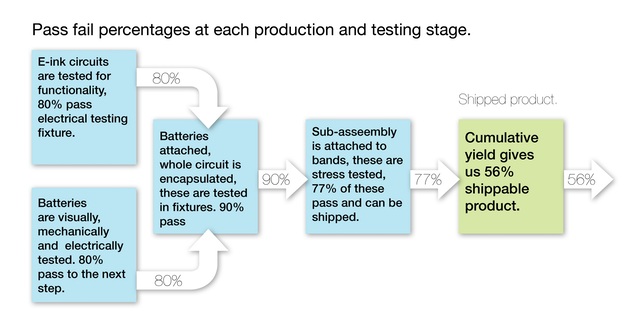

The CST-01 was meant to be the world’s thinnest watch – a 0.8 mm flexible band with an e-ink display. However, due to a variety of issues along the production line, only about half of the watches they produced could be shipped.

Pass fail percentage at each production and test stage

While this is a manufacturing issue at heart, the end result is that cost-per-unit was effectively doubled, rendering the watch’s original price insufficient. Other projects ran into difficulties with component prices, with actual price parts being substantially higher than those originally quoted, or necessary part substitutions outpricing the originals.

What can I do to avoid this?

Plan for the most expensive possible scenario when you set your product’s price. It may be tempting to set a low price for your product to generate more demand, but this won’t benefit you in the long run. Indiegogo recommends setting your product’s price at 3 to 5 times its cost.

#11: Delivered – doesn’t work

A handful of these hardware projects actually made it through the design, prototyping, and production phases and into the hands of consumers, but they were so out-of-line with what was promised, we still consider them “funded-but-failed”.

Two particularly egregious letdowns were the Kreyos smartwatch and the logbar Ring. The Kreyos Meteor was advertised as a waterproof smartwatch with a 7+-day battery life with full voice and gesture control, as well as an extensive app store. The Meteor raised just over $1.5 million on Kickstarter. The campaign looked promising, but the product that made its way to backers had a 24-hour battery life, couldn’t tell time without an active Bluetooth connection, lacked any sort of gesture control, and could be fried by showering with it on. Logbar’s Ring was a similarly optimistic concept, meant to have gesture control sensitive enough that you could trace out words with your fingers and send them as texts. Instead, backers received a “comically unusable” product with gesture control that only worked properly “five to ten percent” of the time.

What can I do to avoid this?

Don’t overpromise. It’s better to overdeliver than underdeliver. The original product you advertise in your campaign should be the most attainable. You can add new layers of functionality as stretch goals after you meet your initial funding, but even those should be within the realm of reason.

Research the technology you intend to use in your product. Even with hundreds of thousands of dollars and a brilliant team, substantial improvements to existing tech are difficult to achieve in short periods of time.

#12: Underestimated demand

Making 100 units of a product requires substantially different manufacturing processes than making 100,000 units. A few project creators based their campaign goals on relatively conservative demand estimates. Some even started their campaigns as projects of passion rather than profit – after materials and assembly costs, they expected to operate at a slight loss. However, a slight loss on every unit of 100,000 quickly becomes a substantial loss.

What can I do to avoid this?

Have contingency plans for varying levels of product demand. Research the manufacturing processes your product would require and make different production process profiles based on the number of units you have to produce.

Keep an eye on your perks. You can restrict the number of times backers can access perk levels. If you have a set number of units that you plan to manufacture, you can control the number of units you’re responsible for by discontinuing that perk. Once you have production up and running, you can start selling your product outright.

#13: Personal problems

In 2010, Schuyler Towne launched a $6,000 crowdfunding campaign to manufacture a set of professional lock picks. When the campaign proved hugely popular, raising $87,000 in total, Towne found himself in over his head. He was among those project creators who had expected to operate at a slight loss for a small batch of products – raising nearly 15 times his goal was not part of the plan. By 2012, Towne was out of funds for producing the lockpicks and deep into the depressive downswing that would leave him hospitalized 4 months later. While no other project creators provided such detailed accounts of their personal struggles, they did report on team members leaving for personal reasons or family matters over the course of their projects.

What can I do to avoid this?

Not a whole lot. There are always matters outside of your control, and this is one of them. Do your best to promote a work environment where you and your team members are able to care for yourselves and your families. Have flexible policies for sick leave, time off, and working from home. Remember to eat well, sleep well, and take vacation when you need it.

#14: Attempted self-assembly

Self-assembly is a viable option for your product only if a) the assembly is simple, b) those involved have some amount of assembly experience, and c) you are only producing a small number of units. Andy Muldowney, the man behind the mPrinter, learned this the hard way. He had originally hoped to make 100 units with the help of his family and friends. By his estimate, they could complete 20 to 25 units a week, easily fulfilling all orders in a reasonable timeline. However, the mPrinter’s popularity led to him being responsible for making over 700 units, which increased his production timeline to 28 weeks instead of 4-5.

What can I do to avoid this?

Set limits for yourself. If demand for your product vastly exceeds what you originally expected, explore other assembly opportunities early on.

Key Takeaways:

tl;dr – Design is hard. Prototyping is hard. Production is hard. There are a ton of ways you can mess up a hardware project, even if you reached your crowdfunding goal. If you want to avoid most major missteps:

- Build the right team.

Your project will need ample insight from designers, software engineers, electronics engineers, and mechanical engineers. You will probably need to consult with a UI/UX designer and industrial engineer, if not regularly work with them. Even if you are completely confident that you can complete the project yourself – and you’re probably wrong – campaigns run by teams raise over 3 times as much cash as those run by individuals. Please, build a team.

When you’re looking for fellow founders / collaborators for your project, sites like FounderDating, Founder2B, and Shapr can help you network with other people interested in starting . For shorter-term contracts, sites like Upworkand Fiverr can connect you with freelancers looking for work.

- Prototype, prototype, prototype.

The more you prototype, the more likely you are to catch major issues early on. You can save a ton of time and money by catching these problems before you multiply them by however many units you’re producing. Kickstarter and Indiegogo provide lists of trusted prototype providers here and here.

- Pick the right manufacturer.

Manufacturing overseas may save you money, but time zones and language barriers can be difficult to navigate. Regardless of your manufacturer’s location, you need to develop a strong relationship and clear lines of communication. The fate (or at least the delivery timeline) of your product is in their hands. Kickstarter and Indiegogo have manufacturer recommendations, too. Dragon Innovation, who is partnering with Kickstarter on their nascent Hardware Studio, also offers services for matching you with the right manufacturer for your product. Maker’s Row provides similar services as well.

You should never underestimate how difficult it is to get a product to market. Together, these failed hardware projects swallowed up $26,074,576 in donations, left the majority of backers empty-handed, and provided the remainder with severely underperforming products. We hope that this breakdown of the challenges failed campaigns faced will help prepare you for the ordeal ahead. Good luck, and if you need help analyzing your parts for manufacturability or getting them made, please get in touch.